Is flax the future of textiles made in France?

Le lin n’a pas disparu des garde-robes, mais sa nature végétale renouvelle le succès de ce tissu de premier plan. Lisse ou chiffonné, avec ses teintes claires et sa légèreté, il fait le bonheur des adeptes de naturalité.

Insulating and anallergic, the natural fibre of flax is a real success. The plant is grown in the north-western half of France. It is ecological, and unlike cotton requires little water for its cultivation, bringing it back to the taste of the day. The industry is in the process of being regenerated and many exciting projects are being created thanks to a very promising market.

French flax continues to invest

This French family business, founded in 1957, is a specialist in tetting, a classic operation of the textile industry that consists in separating hemp or flax fibres from the bark and the woody part of the plant. The growing company has just changed both its name and its size, with a new plant. Installed in Quaëdypre, the French flax Jean Decock opens a new site in Aisne under the impetus of the new generation, the third generation: Quentin Decock, and his cousin Edouard. Two new production lines and 24 jobs were created last May to meet rising demand.

An investment of EUR 12 million has been made which demonstrates the good health of the company and the market. Thanks to this great step forward, it will be able to process 40,000 tonnes of flax at its two sites. Yes, it is. This crop is widely accepted because it requires few inputs and promotes the biological activity of the soil.

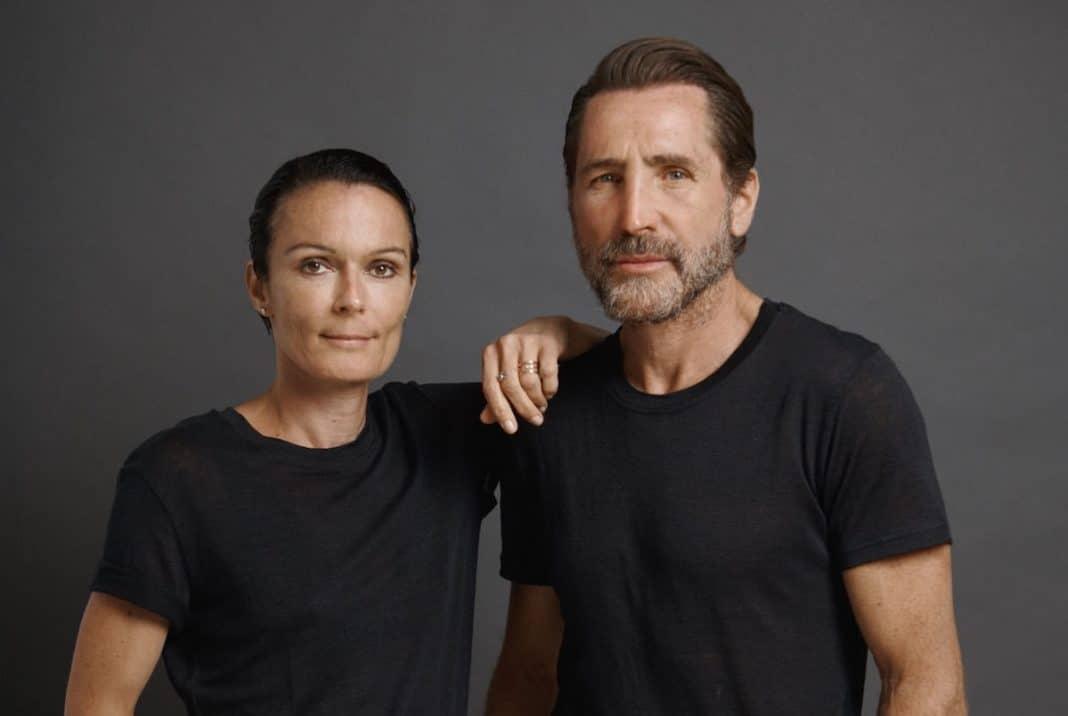

Marion Lemaire for the renewal of the industry

The creator of splice, Marion Lemaire, wants to wear the colors of France high. Although the country is the world's leading textile flax producer, there is no longer a dedicated spinning mill in the country, so the idea of creating a brand made in France was far from obvious. There was nothing to prevent the young woman from venturing into this territory. After studying law and computer science and her marriage, she left for the United States in 1998, a two-year break that strengthened her ability to adapt. As with many women, life continues between work and the birth of three children.

The creation of this family gives rise to other desires, for more naturality. A decade ago, it is very complicated to find 100% French clothing for all members of the family. Here she is starting to create her brand of children's clothing, "naturally small", which was actually launched five years ago. It is not easy for our new entrepreneur, but it is an opportunity to meet some other activists of the made in France, such as Thomas Huriez ("1083"). A broader project is taking shape, based on line.The basic concept is planted: "we grow flax beautifully in France but we Don't go anymore. This is unacceptable. .

And yet, Safilin, the last French mill, closed years ago to settle in Poland. It is with this company and the support of Thomas Huriez that the project takes shape: Safilin will return to France to offer 100% French clothing. An exciting first step that must be realized through the conquest of new customers in order for the adventure to be sustainable. Marion Lemaire hopes that some luxury customers who work abroad will think favourably about this new option available to them, or why not some large distributors, which are particularly interesting in terms of volume.

Since 2020, Marion Lemaire's company SPLICE has been part of the French Forces de l'Industrie accelerator, which assists SMEs in their process of reindustrializing France. A real project to follow closely.

Alsace, the land of textile renewal?

If the textile renewal project materializes, it will be largely thanks to Pierre Schmitt, a former DMC executive, who has taken over companies in great danger in recent years: his Velcorex group, the last velvet company in France, also owns Emmanuel Lang, a specialist in natural materials and thatch weaving, specializing in luxury. Together with Philea and its silks, this new group represents 30 million turnover for 150 employees, a true adventure, because the textile sector is not really the beloved sector of bankers.

As a result, crowdfunding platforms had to be used to finance the last projects. It takes stubbornness and a little anger to tackle a task as complex as the preservation of textile know-how otherwise doomed to extinction. The new flax mill has just started production in Hirsinque. Jeans and shirts are the first clothes to be removed from the factory. It must be said that this experienced entrepreneur is a passionate and stubborn.

"indignant" he is, and that is in part what has allowed him to gather around him former technicians who have the know-how to reassemble the machines. He admits that the health crisis has served these types of projects, in line with the rebirth of French industry. Flax comes from the cooperative Terre de Lin, which brings together the production of some 600 farmers.

Marion Lemaire and Pierre Schmitt are making emules, so two young entrepreneurs Xavier Denis and Tim Muller have in turn decided to participate in this renaissance of the flax industry by creating a mill near Morlaix. Let's bet that all these initiatives will eventually lead to a real renaissance of the sector. As Pierre Schmitt says, "long fibres like hemp and flax are an excellent channel for decarbonizing the industry".

A.F.